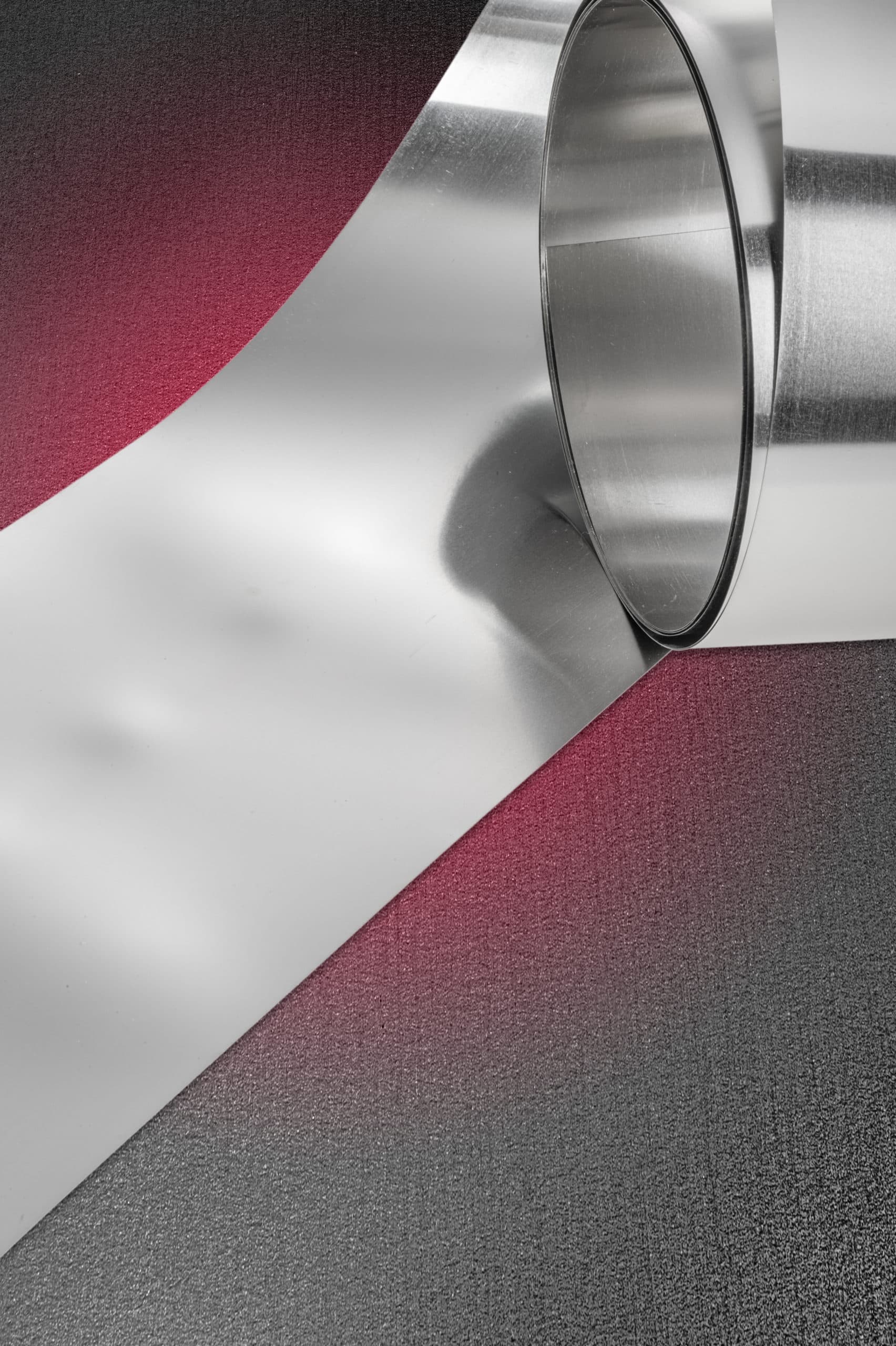

Tantalum Strip

Admat supplies coiled tantalum strip in a wide range of thicknesses and widths. Our strip is precision rolled, annealed and shipped on sturdy cores. Our products are produced to meet typical ASTM, AMS, or specific deep draw specifications, we also welcome customer developed specifications. If you are just engineering your product requirements, our engineers will help you design a specification suited to your application.

Admat offers both powder metallurgy derived and electron beam processed tantalum strip. The powder metallurgy grade tantalum is perfect for deep drawing and stamping applications. It ensures drawn parts have a smooth surface, free of cracks and pits. The isotropic properties of the strip help to avoid erratic can height or “earring”problems. When ordering this tantalum strip, specify “Powder Met Grade” or order to ASTM B708 RO5400. For shallower draws or stamped parts, “Electron Beam Grade” tantalum strip will be ideal. This type of tantalum strip is made from rolling down ingots and slabs that were melted and purified in electron beam furnaces. When ordering this material, reference ASTM B708 RO5200.

For high temperature applications, such as furnace hardware, Admat has grain stabilized tantalum strip. This product is engineered to significantly increase the product life by slowing grain growth at high temperatures.

No matter what your application, let our tantalum experts work with you to develop the proper material requirements for your application.

Available Alloys:

- Tantalum 2.5% Tungsten

- Tantalum 7.5% Tungsten

- Tantalum 10% Tungsten

- Furnace Grade Tantalum

Common Specifications

- ASTM B708 R05200

» Electron Beam Melted (unalloyed) - ASTM B708 R05400

» Powder Metallurgy Grade (unalloyed) - ASTM B708 R05252

» Tantalum 2.5% Tungsten Alloy - ASTM B708 R0255

» Tantalum 10% Tungsten Alloy - AMS 7849 Rev E

» Electron Beam Melted

Available Sizes

for Coiled Tantalum Strip & Foil

.001″

.002” to .003”

.004″ to .015″

.016″ to .020″

4″

6”

12″

25″

Available Purities:

Commercial Grade ( ASTM )

- 3N 99.900% | 3N5 99.950%

- 4N 99.990% | 4N5 99.995%

- 5N 99.999%